Robotic grippers are commonly used to handle parts during transportation. The power source for these grippers can be pneumatic, hydraulic, or electric. Each option has its own advantages and disadvantages depending on the specific application needs and the size of the load. While hydraulic systems offer high power and pneumatic systems provide cost-effecticiency, electric motors should not be overlooked due to their consistency, efficiency, ease of maintenance, and built-in driver functions.

In this article, we will explore how the torque limit function makes brushless motors an excellent solution for grippers.

|

Conventional Gripper Equipped with a pneumatic device, this gripper is designed to pick up a load and transport it to the next process. Problems with Pneumatic Grippers While moving a heavy load of a certain mass, the gripper may drop the load due to inconsistent gripping force. |

The Torque Limit function allows for incremental increases or decreases in motor torque as a percentage of the motor's rated torque. This feature is available on several closed-loop motor systems from Oriental Motor.

|

Practical Application Example The Torque Limit function provides optimized multi-level gripping force to gradually increase the gripping force of a gripper and securely hold a load without damaging it. How It Works The torque of a motor can be increased or decreased by adjusting the current flowing through its windings. The Torque Limit function monitors and controls motor current to limit torque. |

|

How To Use

|

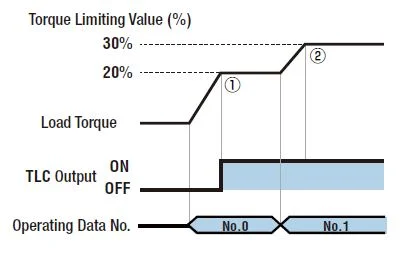

Timing Chart - Torque Limit Function

|

With 16 different speed and torque limit settings, the same BLE2 Series brushless motor and driver can be configured for various loads.

*For closed-loop stepper motor systems, up to 256 settings are offered.

| Output Power | 30 W, 60 W, 120 W, 200 W, 400 W |

| Torque Limit Setting Range* | 0~300% |

| Max Number of Settings | 16 |

| Torque Limit Accuracy* | ±10% |

| Speed Control Range* | 80~4000 r/min |

*The value when the rated torque value is 100%. An error up to a maximum of approximately ±10% (at rated torque and rated speed) may occur between the setting value and generated torque due to factors such as the setting speed, power supply voltage, and motor cable extension length. The BXⅡ Series offers a speed control range of 2~4000 r/min.

Here’s a demo video introducing the BLE2 Series brushless motor and driver, the Alarm Monitor function, and the Torque Limit function.

Need help with your application?

If you're looking for more information or assistance, feel free to reach out to our experts today!

Automatic Drain,Auto Drain Valve,Auto Drainage,Automatic Condensate Drain

Hongrijia Depurate Facility Science & Technology Co.,Ltd. , https://www.yukafilter.com