ESI is thrilled to announce the launch of CThru Metals, a groundbreaking new division within our metal forming and manufacturing operations. This dynamic new unit will focus on producing expanded metal mesh foil products crafted from high-quality, precision-grade metals, featuring thinner gauges, wider coils, and superior durability. At CThru Metals, we're committed to delivering unparalleled performance and reliability in every product we manufacture.

Why Choose Expanded Metal Mesh Foil?

When compared to traditional woven wire or perforated metal, manufacturing expanded metal mesh foil offers significant advantages. Unlike woven wire, which consists of multiple strands that can loosen over time, expanded metal mesh is formed from a single piece of material, ensuring greater durability and consistency. Additionally, it generates significantly less waste during production, making it a more sustainable choice.

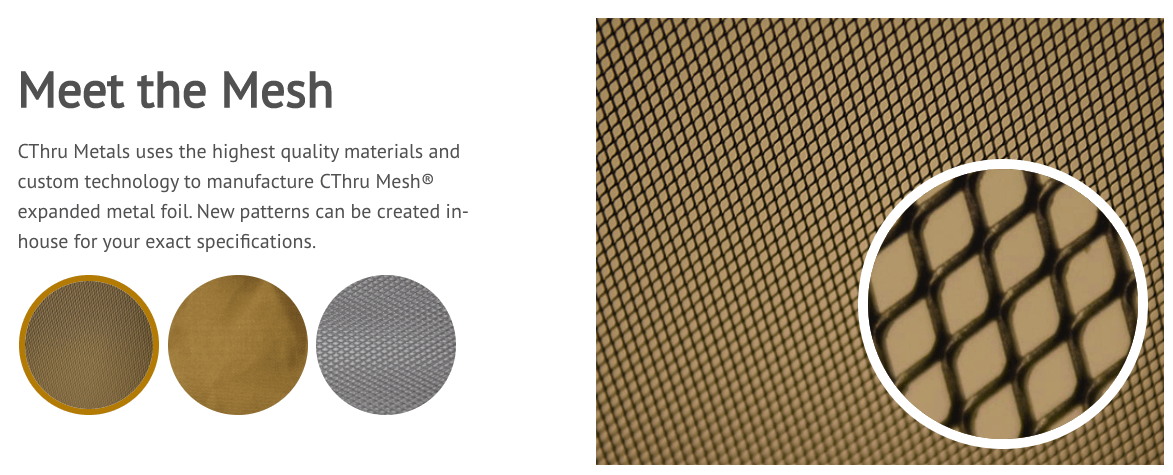

Our engineering team has developed cutting-edge equipment and techniques that allow us to tailor expanded metal foil materials to precise specifications and tolerances. Whether you need stainless steel, copper, aluminum, exotic alloys, or titanium, our experts can create custom mesh solutions tailored to your exact requirements.

In recent years, expanded metal has gained popularity over perforated metal due to its efficiency and reduced waste. For instance, perforated metal often results in 50% scrap when creating panels with 50% perforations. In contrast, expanded metal foil allows for minimal material loss during production. Moreover, we can achieve very tight tolerances, providing clients with highly accurate, consistent, and customized materials. Our diamond sizes range from 0.03 to 0.5 inches, with mesh openings varying between 25 and 5,000 per square inch. We work with metal thicknesses ranging from 0.001†(0.025mm) to 0.016†(0.40mm).

Given the increasing demand for high-performance metal forming across various industries, ESI recognized this as an excellent opportunity to provide superior expanded metal mesh at competitive prices. Our capabilities at CThru Metals include:

- Flattening

- Stretching

- Annealing

- Custom blanking

- Solid sections

Â

Why CThru Metals?

With over three decades as a leader in metal stamping, ESI brings invaluable insights into the growing need for high-quality expanded metal mesh foil in numerous sectors. Leveraging our metal stamping expertise, we’ve engineered innovative, proprietary tools and methods that enable us to fabricate custom shapes and sizes for any unique application.

Some of the products we can produce include:

- Expanded metal foil for lightning-strike protection in aircraft and wind turbine blades

- Expanded metal foil for fuel cells, batteries, electronics, and solar applications

- EMI shielding for sensitive electronics

- Custom metal and plastic mesh filters for filtration systems

All tooling is built in-house, enhancing the benefits of our proprietary processes and equipment. With everything completed under one roof, our customers benefit from rapid turnaround times and unmatched quality assurance.

Over the last 30 years, ESI has achieved remarkable milestones. The creation of CThru Metals represents an exciting phase in our growth trajectory, allowing us to offer even more advanced solutions to our industrial clients. Explore the newly launched CThru Metals website for detailed information about our capabilities.

I’m genuinely excited about what this new division means for the future of metal forming. If you have any questions or would like to discuss potential projects, feel free to reach out! I’d love to hear your thoughts and explore how CThru Metals can support your needs.

Best regards,

Ron Delfini

JIANGMEN PRO-TAYLOR REFRIGERATION CO., LTD. , https://www.protaylor.com

Comments are closed